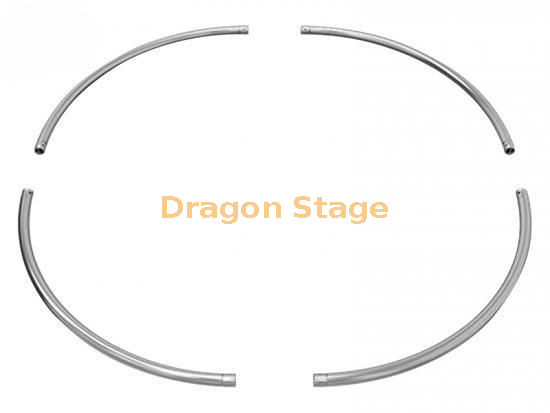

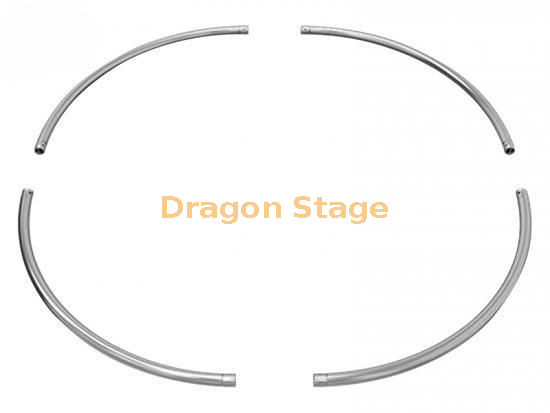

The aluminum circular single tube truss is a structural form that utilizes cylindrical tubes made from aluminum alloy. As the name implies, it is composed of individual circular tubes that are connected to form triangular shapes. This truss configuration offers several advantages for engineering applications.

Being made from aluminum alloy gives this type of truss notable attributes. Aluminum is a lightweight yet durable metal, allowing the truss to support substantial loads without excessive mass. The use of circular tubing also improves the strength-to-weight ratio compared to other cross-sectional shapes. By enclosing the aluminum material completely, the circular form achieves high rigidity even with relatively thin tube walls.

As a single tube truss, it employs solitary aluminum cylinders as the primary structural elements rather than bundled members. This simplifies fabrication as tubes need only be cut to length and joined together rather than more complex built-up sections. Forming triangular configurations from the tubes lends geometric efficiency to the design. The triangles create a stable, self-supporting structure that resists both vertical and horizontal loads effectively.

In summary, the aluminum circular single tube truss utilizes the inherent properties of its materials and geometric shapes to provide a lightweight yet robust structural solution. Its attributes of strength, rigidity, simplicity of fabrication, and efficient load transfer prove advantageous for a variety of engineering applications.