packing weight: 950kg

packing volume: 2cbm

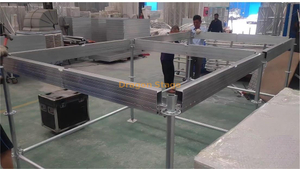

| Item | Specification | Quantity |

| Layer truss | Horizontal Pipe, LR2,L:2M | 51 pcs |

| Diagonal Pipe, LR3,L:2.44M | 44 pcs |

| Pillar,LR1, L:2m | 30 pcs |

| adjustable base,LR4, H:0.25m | 6 pcs |

| steel braces, L:2M,H:0.5M | 4 pcs |

| suspending Layer truss | Horizontal Pipe, LR2,L:2M | 4 pcs |

| Diagonal Pipe, LR3,L:2.44M | 8 pcs |

| Pillar,LR1, L:2m | 2 pcs |

| Motor | Chinese brand, Load:2000kg, Chain length:25m, lifting speed:3.2m/min, 220V-3phrase, output:750W,Ins.class:F,Body | 1 pcs |

| flight case for motor | 1pcs motor in one case | 1 pcs |

| Fibre slings,T4 |

| 1 pcs |

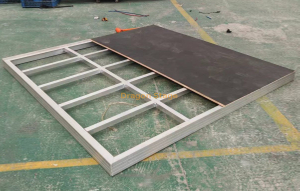

| Truss | CS40, square truss 389*389*2500mm | 1 pcs |

| Double clamp |

| 4 pcs |

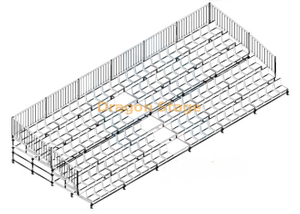

For large-scale outdoor concerts, ensuring optimal sound quality and audience engagement hinges on meticulous audio system deployment. A key element in achieving this is the suspending system, tasked with supporting the weight of the line array while ensuring stability, safety, and precise positioning. This essay will discuss the bespoke application of a Layher suspending system for a line array at 10m, focusing on its unique benefits and considerations.

The Layher system, renowned for its robustness and modularity, offers a customizable solution for various concert setups. For a 10m deployment, the system would necessitate a carefully planned configuration to accommodate the weight of the line array, the wind load, and the desired sound projection. This typically involves using robust Layher towers, interconnected by strong beams and bracing elements, providing a secure platform for the line array speakers.

The custom nature of this solution lies in its adaptability to specific concert requirements. Factors such as the size of the stage, the audience capacity, and the desired sound dispersion will all influence the design of the suspending system. For example, a wider stage may necessitate a greater span between the towers, requiring larger beams and additional bracing for stability. Similarly, the system could be tailored to accommodate angled speaker positions, optimizing sound coverage and minimizing potential sound reflections.

Beyond its structural integrity, the Layher system offers several key advantages. Its modularity allows for easy assembly and dismantling, facilitating efficient setup and breakdown. The pre-engineered components guarantee consistent performance and ensure the system's longevity. Moreover, the system is highly adaptable, allowing for future modifications or expansions as needed.

However, using a Layher suspending system for a line array at 10m comes with certain considerations. The weight of the system itself, along with the line array, must be carefully calculated to ensure it does not exceed the load capacity of the ground beneath it. Wind loads, particularly in open-air venues, can pose a significant challenge and require appropriate bracing and securing. Additionally, thorough inspection and maintenance are crucial to ensure the system's safety and structural integrity throughout the event.