packing weight: 1750kg

packing volume: 10cbm

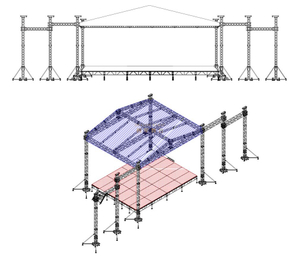

| Item | Specification | Quantity |

| Aluminium assembly stage | topping: 4x8ft

(1.22x2.44m) | wooden | 30 pcs |

| 1.22m stage brace | 40 pcs |

| 2.44m stage brace | 33 pcs |

| stand with extendable tube | 44 pcs |

| Stage adjustable base | 44 pcs |

| Stage Stair | wooden topping | total | 4 | steps | 2 pcs |

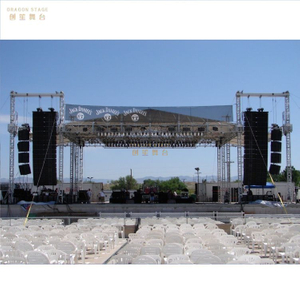

The construction of a custom small aluminum truss stage, even at the relatively modest dimensions of 12.2m x 8.54m, represents a complex engineering undertaking. Success requires a meticulous attention to detail in every aspect of the design and construction process. From the selection of materials and structural analysis to the integration of safety features and compliance with regulations, a multidisciplinary approach is essential. Only through a thorough understanding of structural mechanics, material science, and relevant safety standards can a robust, safe, and cost-effective stage be realized. The utilization of FEA software and consultation with experienced structural engineers are indispensable components in the successful completion of this project. Thorough documentation, including detailed design drawings and load calculations, is crucial for both construction and subsequent maintenance and modification.