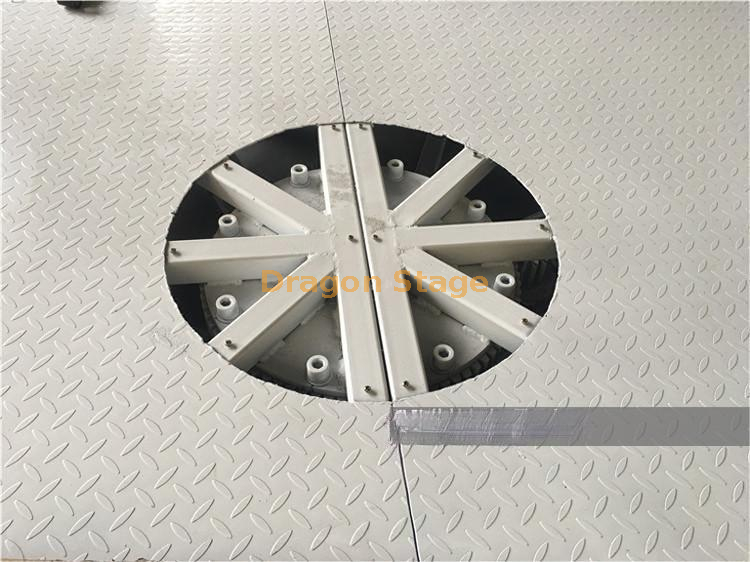

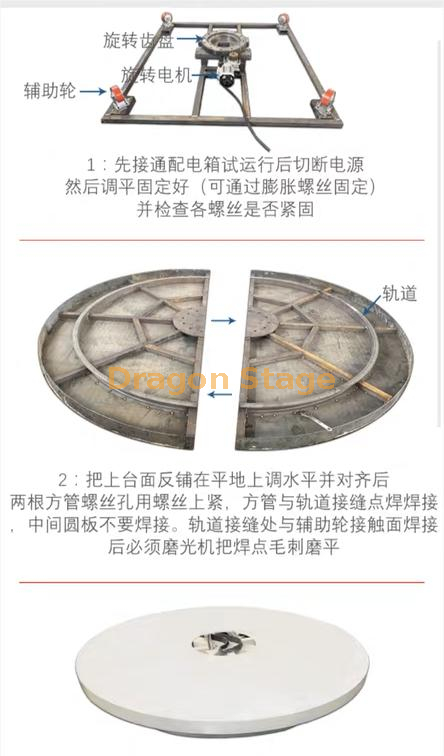

3: Place the assembled upper table in the center on the base, fix it firmly on the rotating gear plate with Allen screws, and check if the auxiliary wheel is in smooth contact with the track. Check if there are any debris below, and try to run it normally. Tighten the screws on the middle cover of the back cover.

4: The rotary table has start/stop buffer protection.

Press the stop button during rotation and wait for the turntable to come to a complete stop before reversing. In emergency situations, use the air switch of the distribution box to cut off the power and stop the emergency. After use, the power should be cut off.

|