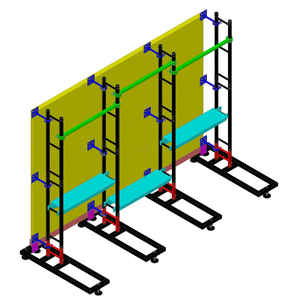

Ground support (stacking system) elements play a critical role in the installation and stability of indoor LED walls, particularly in larger configurations such as a 25m x 3m display. In this context, where precision, durability, and safety are paramount, the choice and implementation of the stacking system elements are of utmost importance.

The dimensions of the LED panels, typically measuring 50cm x 50cm, necessitate a robust support structure to ensure the seamless alignment and structural integrity of the entire display. The ground support elements serve as the foundation upon which the LED panels are mounted, providing stability and support to the entire structure.

When considering a project of this scale, factors such as load-bearing capacity, ease of installation, adjustability, and compatibility with the specific LED panels being used must be carefully evaluated. The stacking system elements should be designed to distribute the weight of the panels evenly, preventing any undue stress on individual components and ensuring the longevity of the display.

Furthermore, the precision of the ground support elements is crucial in achieving a seamless and uniform display. Any misalignment or instability in the stacking system can result in gaps or inconsistencies in the LED wall, detracting from the overall visual impact and effectiveness of the display. Therefore, meticulous attention to detail in the design and installation of the support structure is essential.

In addition to structural considerations, the safety of the installation must be prioritized. The ground support elements should be engineered to withstand external forces such as wind or vibrations, ensuring that the LED wall remains secure and stable in all conditions. Regular inspections and maintenance of the stacking system are also necessary to identify and address any potential issues that may compromise the safety of the display.

packing weight: 1400kg

packing volume: 10cbm

10pcs flightcases

| Length 25m | Height 3m | QTY |

| CL30, ladder truss 289x50x255mm | 0.255m long, 0.3m wide, aluminium, black | 26 |

| CL30, ladder truss 289x50x1000mm | 1m long, 0.3m wide, aluminium, black | 78 |

| Adjustable Clamp plate | aluminium, black,0.190m long | 104 |

| T Base | aluminium, black,0.35*1.25m | 26 |

| T square tube | aluminium, black, 1m long | 25 |

| Horizontal tube | 1M long, 2 ends with clamps,black | 50 |

| Platform | 1M long,black | 25 |