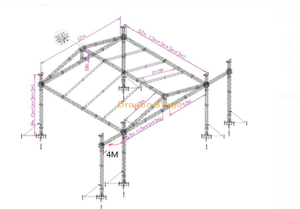

spigot truss system

packing weight: 980kg

packing volume: 7.5cbm

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

| 10.00 m Beam(front) | 2 sets | 3.00 m | 50×3.0 | CS289×289 | 6pcs |

| 2.00 m | 50×3.0 | CS289×289 | 0pcs |

| 1.00 m | 50×3.0 | CS289×289 | 2pcs |

| 10.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | CS289×289 | 6pcs |

| 2.00 m | 50×3.0 | CS289×289 | 0pcs |

| 1.00 m | 50×3.0 | CS289×289 | 2pcs |

| 5.00 m Pillar | 4 sets | 3.00 m | 50×3.0 | CS289×289 | 4pcs |

| 2.00 m | 50×3.0 | CS289×289 | 4pcs |

| 1.00 m | 50×3.0 | CS289×289 | 0pcs |

| beam cube | Spigotcube 289x289 | 0pcs |

| Frame Tower | Spigot Sleeve Block S | 4pcs |

| Steel Base S | 4pcs |

| Top Section S | 4pcs |

| Manual hoist,BA05 2Tons | 4pcs |

| Spigot Hinge Section,Height 1m | 4pcs |

| Fibre sling,BA04,2 tons 3m | 4pcs |

| Long outrigger | 16pcs |

bolt truss system

packing weight: 930kg

packing volume: 7cbm

| Item |

| Specification(squre truss) | Qty |

| length | main tube(mm) | size(mm) |

| 10.00 m Beam(front) | 2 sets | 3.00 m | 50×3.0 | BS300×300 | 6pcs |

| 2.00 m | 50×3.0 | BS300×300 | 0pcs |

| 1.00 m | 50×3.0 | BS300×300 | 2pcs |

| 10.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | BS300×300 | 4pcs |

| 2.00 m | 50×3.0 | BS300×300 | 0pcs |

| 1.00 m | 50×3.0 | BS300×300 | 2pcs |

| 5.00 m Pillar | 4 sets | 3.00 m | 50×3.0 | BS300×300 | 4pcs |

| 2.00 m | 50×3.0 | BS300×300 | 4pcs |

| 1.00 m | 50×3.0 | BS300×300 | 0pcs |

| beam cube | cube 300x300 | 0pcs |

| Frame Tower | Bolt Truss Sleeve Block S | 4pcs |

| Steel Base S | 4pcs |

| Top Section S | 4pcs |

| Manual hoist,BA05 2Tons | 4pcs |

| Spigot Hinge Section,Height 1m | 4pcs |

| Fibre sling,BA04,2 tons 3m | 4pcs |

| Long outrigger | 16pcs |

Aluminum Construction: The truss structure is made from aluminum, which offers a combination of strength, durability, and lightweight properties. Aluminum is commonly used in truss systems due to its ability to bear heavy loads while maintaining structural integrity.

Stage Frame Truss System: The truss structure is specifically designed to create a stable and secure framework for supporting a stage or platform. It consists of interconnected aluminum truss segments that form a rigid structure capable of withstanding the weight of stage equipment, lighting, audio systems, and performers.

Modular Design: The truss structure is typically modular, meaning it can be easily assembled and disassembled by connecting individual truss segments together. This modular design allows for flexibility in creating custom configurations and adapting the structure to different event requirements.

Rigging and Hanging Points: The truss structure often features multiple attachment points or hanging points along the truss segments. These points allow for the suspension of lighting fixtures, audio equipment, video screens, banners, and other stage elements.

Safety and Load Capacity: Truss structures are designed to meet safety standards and are engineered to withstand specific load capacities. The load capacity depends on various factors, such as the truss size, material thickness, and the quality of construction. It's important to ensure that the truss structure is properly engineered to support the intended load requirements for your specific event.

Professional Assembly: Due to the size and complexity of a truss structure measuring 10x10x6m, it is recommended to have professionals or experienced riggers handle the assembly and installation. They have the expertise to ensure the truss structure is assembled correctly, and safety measures are implemented to protect both the crew and performers.

When considering an aluminum stage frame truss structure of this size, it's important to consult with a reputable supplier or an event production company. They can assess your specific event requirements, provide the appropriate truss system design, and ensure compliance with safety standards.