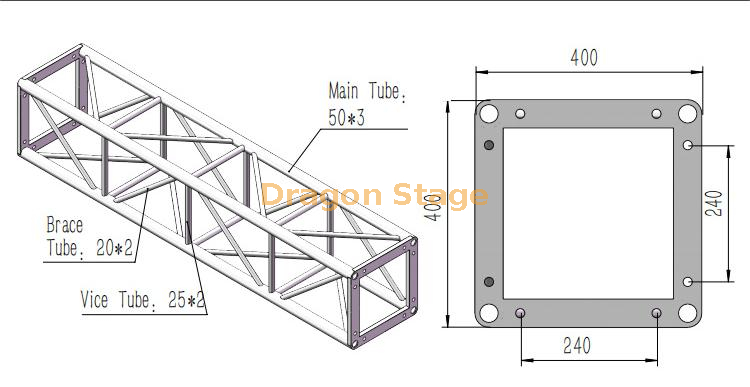

Construction and Design:

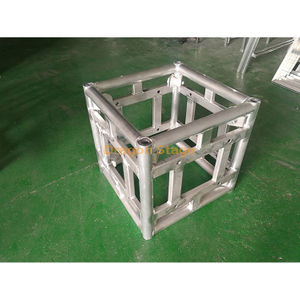

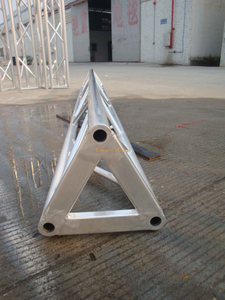

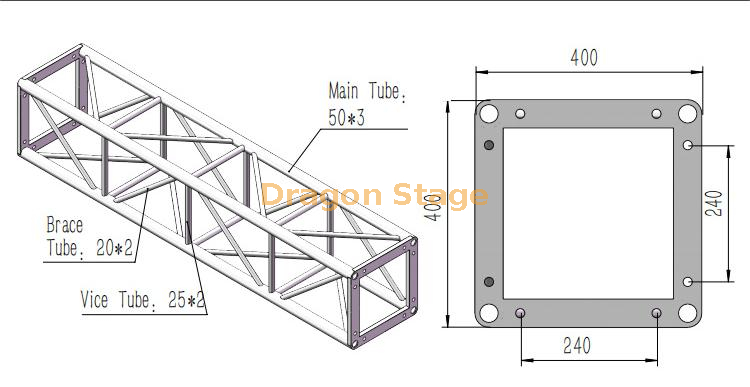

The 300*300 aluminum alloy screw light truss system, as the name suggests, is comprised of individual aluminum truss sections measuring 300mm x 300mm in cross-section. These sections are constructed from high-grade aluminum alloy, offering a lightweight yet sturdy design that can withstand significant loads. The defining characteristic of this system is the use of screw-type connectors, which allow for easy assembly and disassembly without the need for welding or specialized tools. The screw connectors, typically made of high-strength steel, provide secure and reliable connections, ensuring the structural integrity of the entire truss system.

Key Features and Advantages:

Versatility: The modular nature of the 300*300 screw light truss system allows for a wide range of configurations. The individual sections can be connected in straight lines, angled formations, or even complex 3D structures, providing immense flexibility for creating customized lighting and staging arrangements. This versatility makes it suitable for a wide variety of events, from concerts and festivals to corporate conferences and trade shows.

Lightweight and Portable: The use of aluminum alloy ensures the system is lightweight, making transportation and setup relatively effortless. This portability is particularly beneficial for events that require frequent setup and dismantling, such as mobile concerts and touring shows.

Durability and Strength: Despite its lightweight construction, the 300*300 screw light truss system is designed to withstand significant loads. The high-grade aluminum alloy combined with the secure screw connectors provides exceptional strength and stability, ensuring the safety of both equipment and personnel.

Easy Assembly and Disassembly: The screw connectors allow for rapid assembly and disassembly, minimizing setup time and maximizing efficiency. The simple design also reduces the need for specialized skills or tools, making the system accessible to a wider range of users.

Cost-Effectiveness: The 300*300 screw light truss system offers a balance between affordability and performance. The use of durable aluminum alloy and the efficient assembly process result in a cost-effective solution for event lighting and staging requirements.

Safety and Compliance: Reputable manufacturers of this system adhere to stringent safety standards and regulations, ensuring compliance with industry guidelines. They typically provide certifications and documentation to attest to the system's strength, load-bearing capacity, and safety features.

Applications:

The 300*300 screw light truss system finds widespread use across various event production sectors:

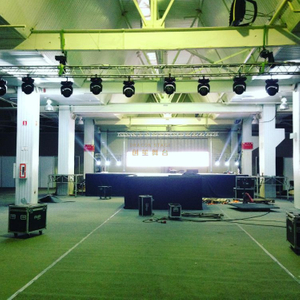

Lighting and Audio Equipment Mounting: The system provides a robust and stable platform for mounting lighting fixtures, speakers, and other audio equipment. Its versatility allows for precise positioning and alignment, optimizing the performance and effectiveness of the equipment.

Staging and Backdrop Support: The truss sections can be used to build staging platforms, backdrops, and other structural elements. Its modular nature enables the creation of custom-designed structures tailored to specific event requirements.

Exhibition and Trade Show Stands: The system is often employed in exhibition and trade show settings to create eye-catching and functional display booths. Its flexibility allows for the construction of multi-level structures and integrated lighting elements.

Outdoor Events and Festivals: The durability and weather resistance of the 300*300 screw light truss system make it ideal for outdoor events. It can withstand harsh weather conditions and provides a stable platform for lighting and sound equipment.

Considerations and Limitations:

While the 300*300 screw light truss system offers numerous advantages, it is important to consider certain aspects:

Weight Limitations: While strong, there are limitations to the weight that can be safely supported by the system. It is crucial to adhere to the manufacturer's load ratings and ensure that the total weight of equipment mounted on the truss does not exceed the recommended limit.

Aesthetic Considerations: The truss system itself has a noticeable industrial aesthetic. If a more aesthetically pleasing structure is required, it may be necessary to incorporate decorative elements or cover the truss with fabric or other materials.

Potential for Rust: Although aluminum is naturally resistant to rust, the screw connectors, typically made of steel, can be susceptible to rust in humid environments. Regular maintenance and cleaning can mitigate this risk.