A Comprehensive Guide to Hanging Line Arrays on Layher Truss Structures

Line array systems are essential components of modern sound reinforcement, delivering exceptional audio quality and coverage across large spaces. Their installation often requires robust and reliable support structures, with Layher truss systems being a popular choice due to their versatility, strength, and modularity. This essay will delve into the intricacies of hanging line arrays on Layher truss structures, providing a comprehensive guide for professionals seeking to achieve safe, efficient, and acoustically optimal setups.

Understanding Layher Truss Structures for Line Array Systems:

Layher truss systems offer a diverse range of configurations tailored to different needs. For hanging line arrays, two primary structures stand out:

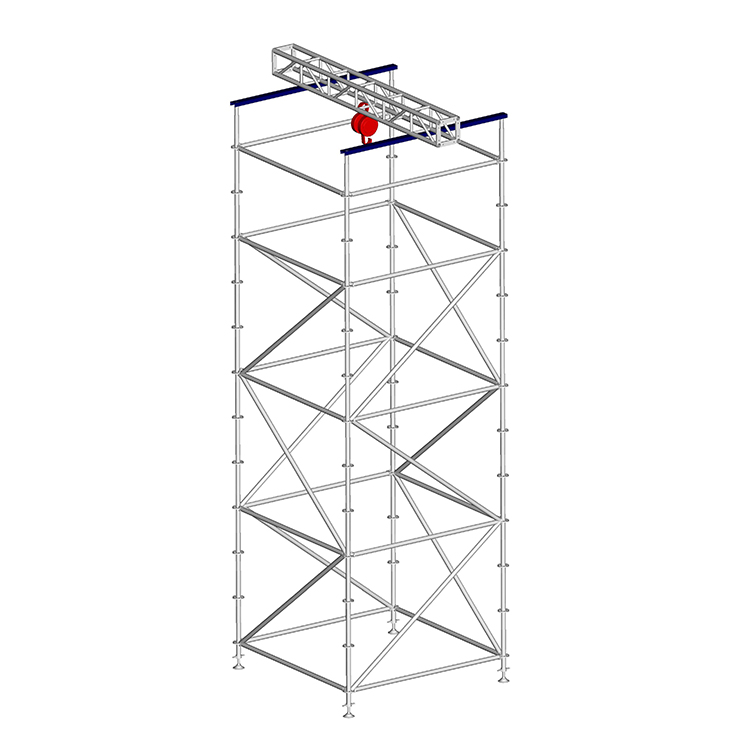

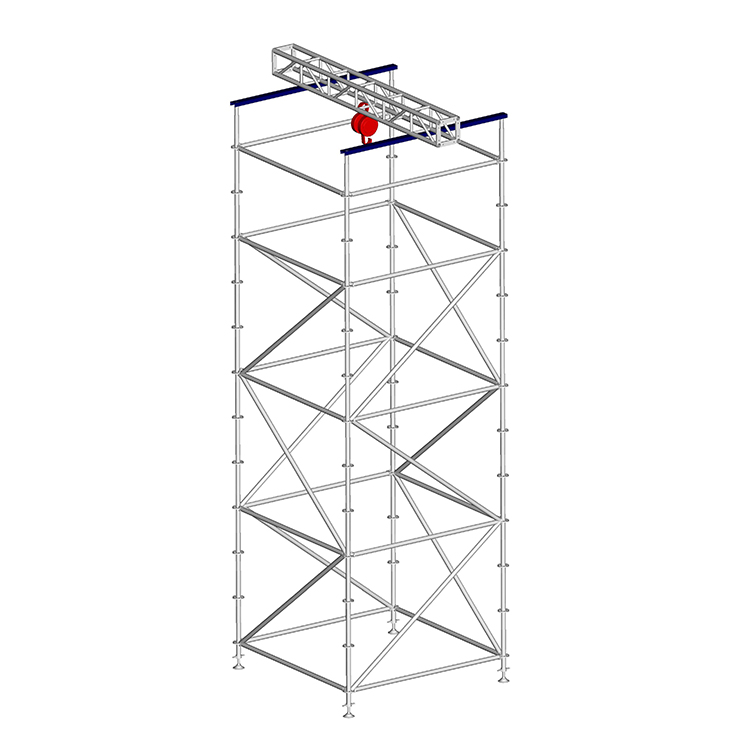

1. Upright Layher Truss Structure: This configuration resembles a traditional speaker tower, with vertical truss sections stacked upon each other to form a stable and upright structure. The simplicity of this design makes it ideal for smaller line arrays and situations where a straightforward hanging solution is required.

2. Cantilever Layher Truss Structure: This configuration involves extending a truss structure horizontally from a supporting wall. This allows for greater reach and flexibility, particularly when hanging larger line arrays or requiring a specific placement in relation to the audience. It is often used to create a "truss wall," a visually prominent element that integrates seamlessly with the event design.

Components for Secure Line Array Hanging:

Both Upright and Cantilever Layher structures employ specific components for securely hanging line array systems:

A. Upright Layher Truss Structure:

Hanging Beam: A robust beam placed atop the final truss section provides a dedicated platform for the hoist system.

Hoist System: A reliable hoist system with sufficient lifting capacity is crucial for safely raising and lowering the line array.

Safety Chains and Cables: Redundant safety chains or cables are essential for preventing catastrophic failure in case of hoist malfunction.

B. Cantilever Layher Truss Structure:

Suspending Structure: This comprises additional truss sections, braces, and brackets that extend from the supporting wall to create a stable and secure overhang.

Brace Trusses: Diagonal braces are critical for reinforcing the cantilever structure and preventing instability.

Bracket Layher Bars: Multiple bracket bars are used to connect the suspending structure to the main wall, providing extra support and ensuring structural integrity.

Double Bracket Bars: For larger and heavier line arrays, double bracket bars are recommended to distribute weight evenly and increase overall safety.

Building a Cantilever Layher Truss Structure:

Creating a cantilever structure demands careful planning and execution. Here's a step-by-step guide:

1. Layher Wall Construction: Begin by establishing a solid and properly braced Layher wall to serve as the foundation for the cantilever structure. This wall should be sufficiently strong to support the weight of the extending truss and the line array.

2. Grid Installation: Install a grid of Layher truss sections extending horizontally from the wall. Each section should be secured with appropriate locking mechanisms.

3. Hanging Pillar Construction: For each grid section, build a "hanging pillar" consisting of vertical truss sections connected by horizontal and bracket bars. This pillar should be securely linked to the wall front.

4. Double Bracket Bars:If the line array is large and heavy, double bracket bars are recommended. This creates a redundant system for weight distribution and increased safety.

5. Brace Truss Integration: Strategically position brace trusses to ensure the entire cantilever structure is reinforced against potential forces and prevent sagging.

Safety Considerations:

Safety is paramount when working with line array systems and Layher truss structures. Here are some essential considerations:

Load Calculations: Carefully calculate the maximum weight the structure can support and ensure that the line array and any additional equipment do not exceed this limit.

Professional Engineers: Engage professional engineers to assess the structural integrity of the Layher truss system, especially for larger and more complex installations.

Rigging Certification: Ensure that all personnel involved in rigging operations possess valid rigging certifications and are trained in safe working practices.

Regular Inspections: Conduct regular inspections of the truss structure, hanging hardware, and hoist systems to identify any signs of wear or damage.

Conclusion:

Hanging line arrays on Layher truss structures requires a thorough understanding of the available configurations, components, and safety practices. By carefully planning, selecting the appropriate structure, and implementing safe rigging procedures, professionals can confidently install and operate line array systems, delivering exceptional sound quality and creating memorable event experiences.