Steel scaffolding Layher truss stages combine the versatility of Layher scaffolding systems with truss structures to create a robust and flexible stage setup for various events. Here's a breakdown of the key features and benefits:

Layher Scaffolding: Layher is a well-known brand in the scaffolding industry, offering high-quality and modular scaffolding systems. Steel scaffolding Layher truss stages utilize Layher scaffolding components as the base structure. Layher scaffolding is renowned for its quick assembly, sturdy construction, and adaptability to different configurations.

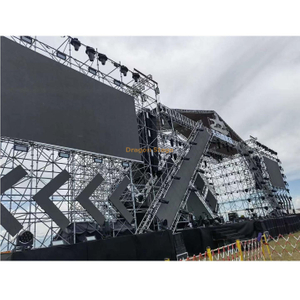

Truss Stage Design: The Layher scaffolding system is integrated with truss structures to create a stage platform. Trusses are typically made of steel and provide excellent load-bearing capacity while maintaining a lightweight design. Truss stages offer versatility in terms of stage shape, size, and height, allowing for customization based on event requirements.

Stability and Safety: Steel scaffolding Layher truss stages provide a stable and secure platform for performers, equipment, and event attendees. The combination of Layher scaffolding and truss structures ensures structural integrity and adherence to safety standards. The load-bearing capacity of trusses allows for heavy equipment, lighting fixtures, and audio systems to be safely suspended.

Flexibility and Customization: Layher scaffolding systems are known for their modular design, which allows for easy customization and adaptability. Steel scaffolding Layher truss stages can be configured in various shapes, sizes, and heights to suit different event spaces and requirements. The modular nature of the scaffolding system also facilitates quick assembly and teardown.

Accessories and Add-ons: Steel scaffolding Layher truss stages can be equipped with additional accessories and add-ons to enhance functionality and aesthetics. This can include safety railings, stairs, ramps, canopies, roof systems, lighting trusses, LED screens, and banners, among others. These accessories help create a complete stage setup and enhance the visual appeal of the event.

Durability: Steel scaffolding and truss structures are known for their durability and ability to withstand demanding conditions. They are resistant to weather elements and provide a long-lasting solution for event stages.

Versatile Applications: Steel scaffolding Layher truss stages are suitable for a wide range of events, including concerts, festivals, corporate functions, trade shows, exhibitions, and more. Their flexibility and adaptability make them suitable for both indoor and outdoor venues.

When considering a steel scaffolding Layher truss stage, it is essential to work with experienced professionals who have expertise in stage design and construction. They can provide guidance on the appropriate configuration, safety considerations, and local regulations to ensure a successful and compliant stage setup for your event.