Publish Time: 2023-09-07 Origin: Site

The Essential Guide to Bolting Aluminum Plate Trusses

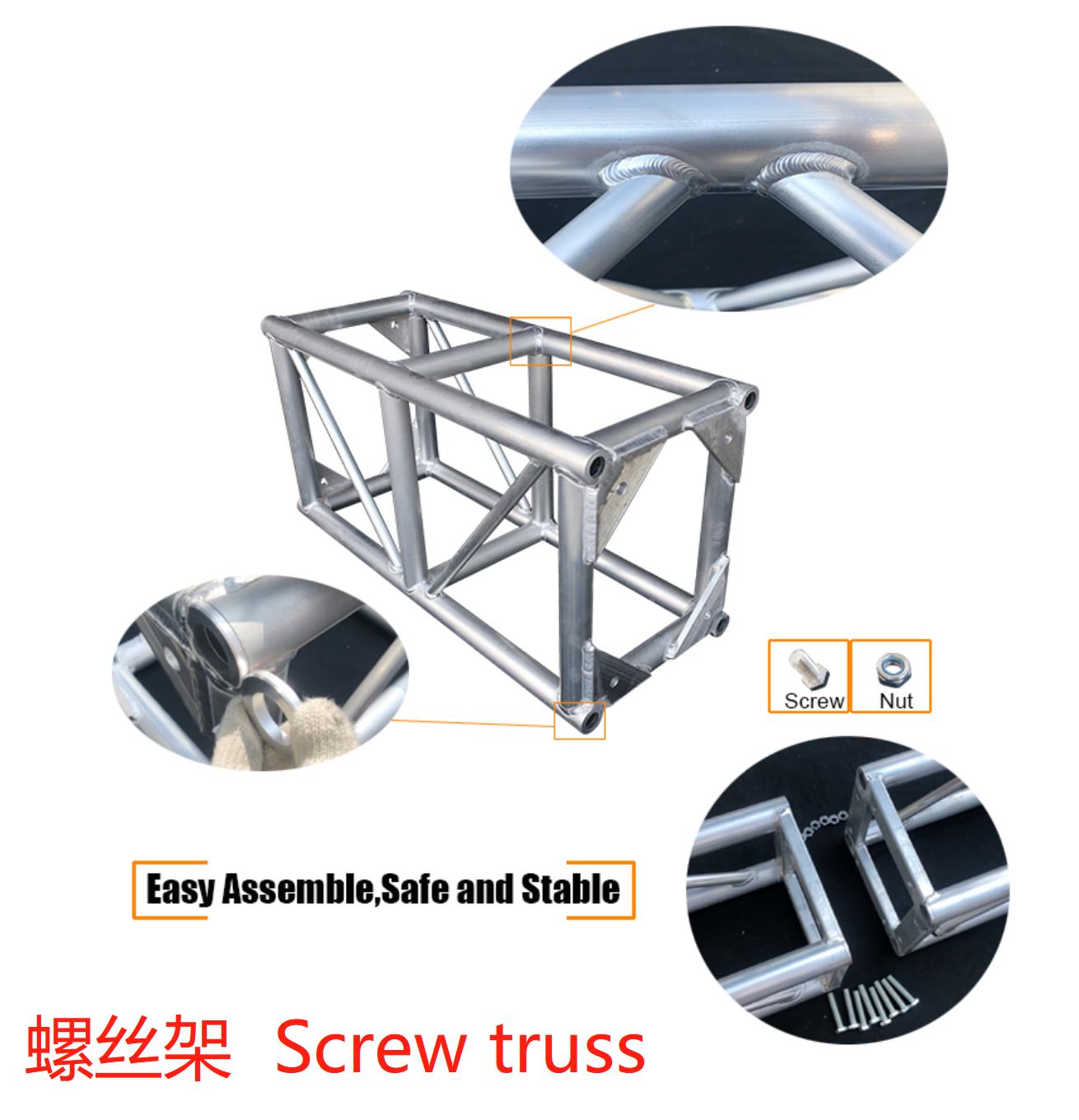

In the world of construction, stage production, and various industrial applications, the joining of aluminum plate trusses is a common requirement. This process relies on steel bolts, nuts, and washers to securely fasten two aluminum plates together. In this article, we will explore the fundamentals of bolting aluminum plate trusses, emphasizing the importance of proper technique and precautions for a safe and secure connection.

Understanding the Components

Before delving into the specifics of bolting aluminum plate trusses, it's essential to understand the key components involved:

1.Steel Bolts: These are the primary fasteners used to connect aluminum plates in a truss system. Bolts are available in various sizes and are typically made of steel for durability.

2.Nuts: Nuts are threaded onto the bolts and play a crucial role in holding the plates together. They come in different types, such as hex head nuts, to accommodate the specific bolt design.

3.Washers: Washers are thin, flat discs that are placed between the nut and the aluminum plates. They serve multiple purposes, including protecting the aluminum from damage caused by the pressure of the nut.

The Bolting Process

Proper bolting of aluminum plate trusses involves several key steps to ensure a secure and safe connection:

1.Washer Placement: Two washers are typically used for each bolt connection. These washers are positioned on either side of the aluminum plate, serving as a protective barrier between the plate and the nut. This helps prevent damage to the aluminum surface during tightening.

2.Using a Socket Wrench: To tighten the nut onto the bolt, a socket wrench is the recommended tool. The use of a socket wrench allows for precise control over the torque applied to the nut.

3.Tightening the Nut: The nut should be tightened until it is snug and secure, with no visible gap between the aluminum plates. This ensures that the truss connection is stable and will not come loose during use.

4.Avoiding Over-Tightening: It is crucial not to over-tighten the nuts, as this can result in damage to the aluminum plates or make it difficult to remove the nuts in the future. The bolts should be tight enough to ensure a secure connection but not excessively so.

Safety Considerations

Ensuring the safety of any structure, especially one involving overhead loads, is paramount. Here are some vital safety considerations when bolting aluminum plate trusses:

1.Secure Connections: Before lifting or loading the truss, it is essential to verify that all bolted connections are tight and secure. Loose connections can compromise the integrity of the structure and pose significant safety risks.

2.Regular Inspections: Periodic inspections of bolted connections are crucial to identify any signs of wear, loosening, or damage. Maintenance and timely tightening of bolts should be part of routine safety protocols.

3.Proper Torque: The use of a socket wrench allows for controlled torque application. Ensure that the nuts are tightened to the appropriate level without exceeding it.

In conclusion, bolting aluminum plate trusses is a fundamental process in various industries, from construction to entertainment. Proper technique, including the use of steel bolts, nuts, and washers, is essential for achieving secure connections while safeguarding the integrity of the aluminum plates. By following these guidelines and prioritizing safety, you can ensure the reliability and durability of your truss structures, providing peace of mind in various applications.

FOSHAN DRAGON STAGE

No.7,Xiaxi Industrial Area,Heshun,Nanhai District,Foshan,528241,Guangdong,China.

+86 136 3132 8997