Publish Time: 2023-06-13 Origin: Site

Introduction: Aluminum scaffolding ladders have gained significant popularity across industries due to their lightweight construction, portability, and safety features. These specialized ladders offer a secure and efficient solution for accessing elevated areas during construction, maintenance, and various work activities. In this article, we will explore the features, benefits, and different types of aluminum scaffolding ladders.

Features and Benefits: Aluminum scaffolding ladders possess several key features that make them highly desirable in the workplace. Their lightweight design allows for easy transportation and maneuverability, without compromising on strength and durability. The aluminum alloy used in their construction ensures both sturdiness and resistance to corrosion, ensuring a long lifespan for the ladder. Additionally, these ladders are equipped with various safety features, such as anti-slip rungs, guardrails, and locking mechanisms, to provide a secure platform for workers at elevated heights.

Types of Aluminum Scaffolding Ladders: There are three main types of aluminum scaffolding ladders, each designed to fulfill specific requirements.

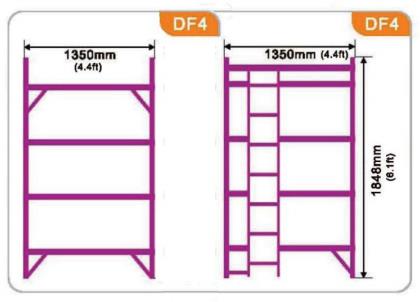

1. Scaffolding Frame-Integrated Ladder: This ladder type is a built-in component of the scaffolding frame. It enables users to climb the scaffolding from the side, providing access to different working levels. The integration of the ladder within the frame ensures stability and ease of use.

2. Inclined Step Stair: Inclined step stairs are the most common type of aluminum scaffolding ladder. They act as connecting rods between two scaffolding frames, providing access from one working platform level to another. These ladders are often used in double-wide scaffolding systems and occupy half the space on the inner side of the scaffolding. It is important to install all inclined ladders in the same direction for consistency.

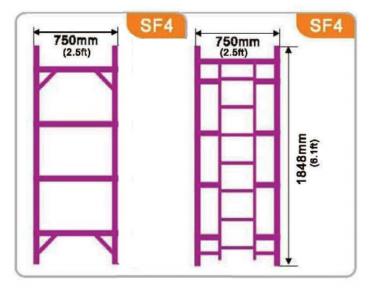

3. Hanging Ladder: Hanging ladders are approximately 0.75m wide and can be used in both double scaffolding and double-wide scaffolding configurations. They are hung using hooks on the scaffolding frame rungs, one level below the upper working platform and one level above the lower working platform. In double scaffolding, it is recommended to install the ladders in a zig-zag pattern to distribute the load evenly and prevent the scaffolding tower from tipping over. In single scaffolding, trap door working platforms are used, and the ladders should be evenly installed across the entire scaffolding space to avoid imbalanced loads.

Conclusion: Aluminum scaffolding ladders provide a versatile and efficient solution for accessing elevated areas in a wide range of industries. With their lightweight yet sturdy design, portability, and advanced safety features, these ladders ensure worker safety and productivity during construction, maintenance, and other tasks. The different types of aluminum scaffolding ladders, such as the integrated ladder, inclined step stair, and hanging ladder, cater to specific requirements and facilitate safe movement between working platforms. By incorporating these ladders into projects, businesses can enhance efficiency, safety, and overall work quality at elevated heights.

FOSHAN DRAGON STAGE

No.7,Xiaxi Industrial Area,Heshun,Nanhai District,Foshan,528241,Guangdong,China.

+86 136 3132 8997