Publish Time: 2023-06-10 Origin: Site

Introduction: Aluminum scaffolding is a versatile and widely used tool in the construction and maintenance industry. One of its fundamental components is the main frame, which serves as the backbone of the entire structure. In this article, we will explore the significance of the main frame in aluminum scaffolding systems, its structural features, and its modular design options.

1. The Crucial Role of the Main Frame: The main frame of aluminum scaffolding is a robust, welded component that bears the majority of the vertical loads. It provides stability and strength to the entire scaffolding structure, ensuring the safety of workers operating at heights. By supporting the horizontal and inclined connecting bars, the main frame forms a unified and sturdy framework.

2. Connecting Bars and Attachment: Working in tandem with horizontal and inclined connecting bars, the main frame facilitates the integration of various scaffold components. These connecting bars are attached to the main frames, allowing for the assembly of a comprehensive scaffolding structure. The secure attachment of these bars enhances the stability and load-bearing capacity of the scaffolding system.

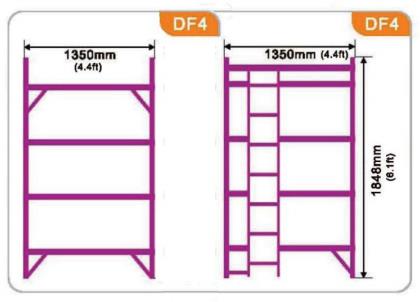

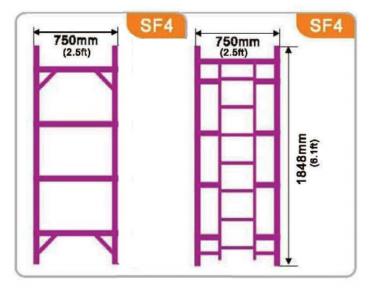

3. Types of Main Frames: a. Rungs-Only Main Frame: One type of main frame consists solely of rungs, providing a modular framework for the attachment of connecting bars. This configuration enables easy customization and adaptability, making it suitable for a wide range of construction projects. b. Rungs and Climbing Ladders Main Frame: Another type of main frame features both rungs and climbing ladders. It serves the same purpose as the rungs-only frame but also includes integrated climbing ladders for vertical access, enhancing worker mobility and convenience.

4. Modular Design and Width Options: The main frame of aluminum scaffolding is designed with modularity in mind. The rungs are standardized, allowing for seamless compatibility between different frames and components. The main frame is available in various rung configurations, including 3-rung, 4-rung, and 5-rung frames, catering to specific project requirements.

In addition to rung variations, the main frame can also be divided into two width options: a. Double Width Frame: With a width of 1.35 meters, the double width frame provides a broader working platform, accommodating multiple workers simultaneously. This frame type is ideal for projects that require increased workspace or heavy-duty equipment. b. Single Width Frame: The single width frame measures 0.75 meters wide, offering a more compact and versatile solution. It is suitable for projects with space constraints or those that require maneuverability in narrow areas.

Conclusion: The main frame plays a critical role in the stability and load-bearing capacity of aluminum scaffolding systems. It serves as the solid foundation for the scaffolding structure, supporting the connecting bars and other components. With its modular design, standardized rungs, and width options, the main frame provides flexibility and adaptability for a range of construction projects. By understanding the importance of the main frame, one can ensure the safe and efficient use of aluminum scaffolding in vertical access applications.

FOSHAN DRAGON STAGE

No.7,Xiaxi Industrial Area,Heshun,Nanhai District,Foshan,528241,Guangdong,China.

+86 136 3132 8997