**Concert Roof Stage with LED Speaker Truss Tower**

**Introduction**

In the realm of live entertainment, creating an immersive and unforgettable experience for audiences is paramount. Concert roof stages play a crucial role in achieving this objective, providing a platform for performers to connect with their fans and deliver captivating performances. The integration of LED speaker truss towers into these stages further enhances the visual and auditory impact, creating a truly extraordinary spectacle.

**Design and Dimensions**

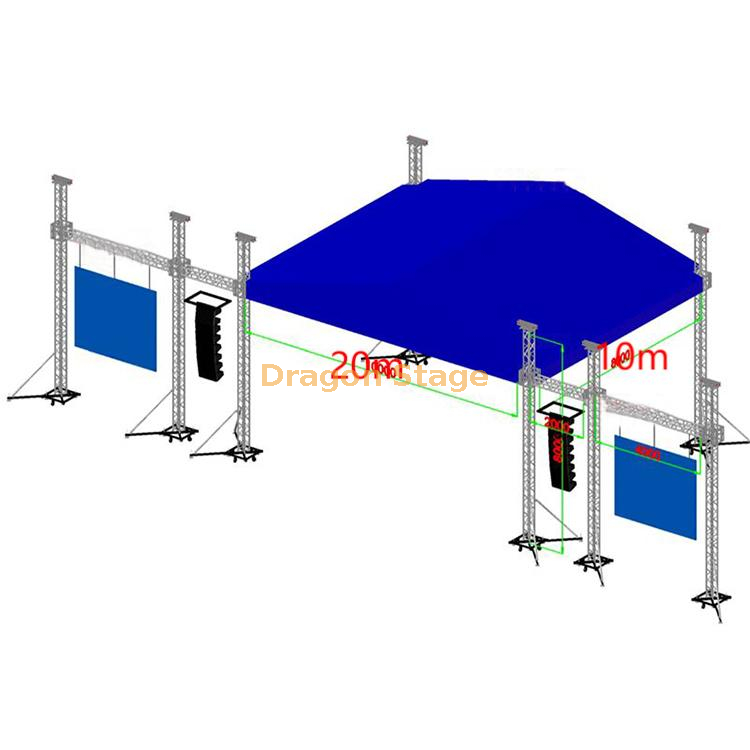

The concert roof stage with LED speaker truss tower is a meticulously engineered structure designed to meet the specific requirements of large-scale events. The main body of the stage measures an impressive 20 meters in length, 10 meters in width, and 7 meters in height. This ample space allows for a wide range of stage configurations, accommodating multiple performers, instruments, and elaborate stage sets.

The speaker truss tower, located at the center of the stage, is 2 meters wide and serves as the primary sound reinforcement system. Its strategic placement ensures optimal sound distribution throughout the venue, delivering crystal-clear audio to every corner of the audience. The LED screen truss tower, situated behind the speaker truss tower, is 4 meters wide and provides a vibrant and captivating visual backdrop for the performance.

**LED Technology**

The LED screens integrated into the truss towers are a key feature of this stage design. These high-resolution LED panels offer exceptional brightness and clarity, allowing for the display of stunning visuals, animations, and live video footage. The LED technology enables seamless transitions between content, creating a dynamic and engaging visual experience that complements the live performance.

**Structural Integrity**

The concert roof stage is constructed using robust and durable materials to ensure its stability and longevity. The truss towers are made of lightweight aluminum alloy, providing strength and rigidity while minimizing weight. The main body of the stage is supported by a network of steel beams, ensuring a solid foundation for the entire structure.

**Versatility and Flexibility**

The modular design of the concert roof stage allows for a high degree of versatility and flexibility. The truss towers can be easily reconfigured to accommodate different stage layouts and venue sizes. The LED screens can also be customized to display a wide range of content, from band logos and artist profiles to promotional videos and live camera feeds.

**Conclusion**

The concert roof stage with LED speaker truss tower is a state-of-the-art performance platform that combines cutting-edge technology with exceptional design. Its ample space, powerful sound system, and vibrant LED visuals create an immersive and unforgettable experience for audiences. The stage's versatility and flexibility make it suitable for a wide range of events, from intimate concerts to large-scale festivals. As the live entertainment industry continues to evolve, this innovative stage design is poised to set new standards for performance excellence.

packing weight: 3700kg

packing volume: 35cbm

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| 20.00 m Beam(front) | 2 sets | 3.00 m | 50×3.0 | CS500×600 | 12pcs | |||

| 2.00 m | 50×3.0 | CS500×600 | 2pcs | |||||

| 1.00 m | 50×3.0 | CS500×600 | 0pcs | |||||

| 10.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | CS500×600 | 6pcs | |||

| 2.00 m | 50×3.0 | CS500×600 | 0pcs | |||||

| 1.00 m | 50×3.0 | CS500×600 | 2pcs | |||||

| 6.00 m Pillar | 4 sets | 3.00 m | 50x3.0 | CS350×350 | 8pcs | |||

| 2.00 m | 50x3.0 | CS350×350 | 0pcs | |||||

| 1.00 m | 50x3.0 | CS350×350 | 0pcs | |||||

| beam cube | Spigot cube 500x600 | 0pcs | ||||||

| Frame Tower | Spigot Sleeve Block M | 4pcs | ||||||

| Steel Base M | 4pcs | |||||||

| Top Section M | 4pcs | |||||||

| Manual hoist,BA05 2Tons | 4pcs | |||||||

| Spigot Hinge Section,Height 1m | 4pcs | |||||||

| Fibre sling,BA04,2 tons 3m | 4pcs | |||||||

| Long outrigger | 16pcs | |||||||

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| Roof Pillar | 2 sets | 2.00 m | 50×3.0 | CS289×289 | 2pcs | |||

| 10.00 m Top Beam | 1 sets | 3.00 m | 50×3.0 | CS289×289 | 3pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 0pcs | |||||

| 1.00 m | 50×3.0 | CS289×289 | 1pcs | |||||

| 10.20 m Oblique Beam | 4 sets | 3.00 m | 50×3.0 | CS289×289 | 8pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 4pcs | |||||

| 2.20 m | 50×3.0 | CS289×289 | 4pcs | |||||

| 10.20 m Ladder truss | 8 sets | 3.00 m | 50×3.0 | CL30,289*50 | 16pcs | |||

| 2.00 m | 50×3.0 | CL30,289*50 | 8pcs | |||||

| 2.20 m | 50×3.0 | CL30,289*50 | 8pcs | |||||

| Roof Components | roof conner 4 ways, use for roof beam truss | CS289×289 | 2pcs | |||||

| roof conner 5 ways, use for roof beam truss | CS289×289 | 0pcs | ||||||

| Connect plate with clamp | 2pcs | |||||||

| Single clamp | 16pcs | |||||||

| Double clamp | 8pcs | |||||||

| roof canopy material:pvc, Blue Colour or customized. | 343.36 | 1pcs | ||||||

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| 6.00 m Wings Beam | 4 sets | 3.00 m | 50×3.0 | CS500×600 | 4pcs | |||

| 2.00 m | 50×3.0 | CS500×600 | 4pcs | |||||

| 1.00 m | 50×3.0 | CS500×600 | 4pcs | |||||

| 6.00 m Wings Pillar | 4 sets | 3.00 m | FALSE | CS350×350 | 8pcs | |||

| 2.00 m | FALSE | CS350×350 | 0pcs | |||||

| 1.00 m | FALSE | CS350×350 | 0pcs | |||||

| Wings Tower | Spigot Sleeve Block M | 4pcs | ||||||

| Steel Base M | 4pcs | |||||||

| Top Section M | 4pcs | |||||||

| Manual hoist,BA05 2Tons | 4pcs | |||||||

| Spigot Hinge Section,Height 1m | 4pcs | |||||||

| Fibre sling,BA04,2 tons 3m | 4pcs | |||||||

| Long outrigger | 16pcs | |||||||

| Truss Accessory | Conical coupler & Safrty clip & pin | whole set | ||||||

Best Practices for Proper Handling and Maintenance of Aluminum Trusses

Casting Brilliance: Mastering Lighting Truss Layout for Stunning Visuals

Behind the Scenes: Exploring Lighting Trusses and Studio Setup

How To Hang Lights On Truss - A Guide to Using Different Lighting Clamps

How to Prevent 200x200mm Aluminum Truss Deforming During the Welding

Understanding the Time-intensive Nature of Club Truss Production

FOSHAN DRAGON STAGE

No.7,Xiaxi Industrial Area,Heshun,Nanhai District,Foshan,528241,Guangdong,China.

+86 136 3132 8997