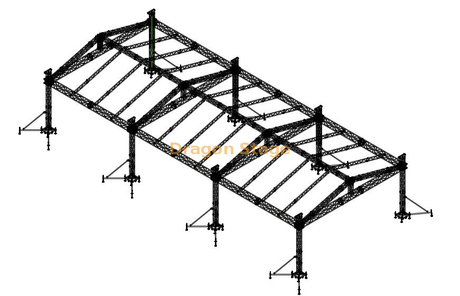

The truss roof cover system, with its meticulously engineered framework, provides a protective and versatile solution for outdoor sports fields. Designed to withstand the elements and create a comfortable environment for athletes and spectators alike, this system offers a multitude of benefits that contribute to the overall success of sports programs and the communities they serve.

One of the primary advantages of this system lies in its ability to shield participants from the harsh effects of weather, including intense sunlight, precipitation, and strong winds. By creating a covered space, the truss roof cover system ensures that sporting events and practices can be conducted uninterrupted, regardless of the prevailing climatic conditions. This feature not only enhances the overall experience for players and spectators but also extends the usability of the facility, allowing for year-round utilization.

Furthermore, the structural integrity of the truss roof cover system is a testament to the advanced engineering principles that govern its design. The robust framework, composed of strategically positioned trusses, distributes the weight of the roof evenly, ensuring the stability and longevity of the structure. This level of durability is crucial in maintaining the safety and reliability of the facility, providing a secure environment for athletic activities.

In addition to its functional attributes, the Outdoor Sport Field Truss Roof Cover System also boasts a visually appealing aesthetic. The harmonious integration of the structural elements and the choice of materials contribute to an overall design that is both practical and aesthetically pleasing. This integration of form and function enhances the overall appeal of the sports facility, creating a sense of pride and community ownership among its users.

packing weight: 3700kg

packing volume: 24cbm

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| 15.00 m Beam(front) | 4 sets | 3.00 m | 50×3.0 | CS389×389 | 20pcs | |||

| 2.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| 1.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| 24.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | CS389×389 | 12pcs | |||

| 2.00 m | 50×3.0 | CS389×389 | 6pcs | |||||

| 1.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| 5.00 m Pillar | 8 sets | 3.00 m | 50×3.0 | CS289×289 | 8pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 8pcs | |||||

| 1.00 m | 50×3.0 | CS289×289 | 0pcs | |||||

| beam cube | Spigot cube 389x389 | 0pcs | ||||||

| Frame Tower | Spigot Sleeve Block S | 8pcs | ||||||

| Steel Base S | 8pcs | |||||||

| Top Section S | 8pcs | |||||||

| Manual hoist,BA05 2Tons | 8pcs | |||||||

| Spigot Hinge Section,Height 1m | 8pcs | |||||||

| Fibre sling,BA04,2 tons 3m | 8pcs | |||||||

| Long outrigger | 32pcs | |||||||

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| Roof Pillar | 4 sets | 1.50 m | 50×3.0 | CS289×289 | 4pcs | |||

| 24.00 m Top Beam | 1 sets | 3.00 m | 50×3.0 | CS289×289 | 6pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 3pcs | |||||

| 1.00 m | 50×3.0 | CS289×289 | 0pcs | |||||

| 7.70 m Oblique Beam | 8 sets | 3.00 m | 50×3.0 | CS289×289 | 16pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 0pcs | |||||

| 1.70 m | 50×3.0 | CS289×289 | 8pcs | |||||

| 7.70 m Ladder truss | 18 sets | 3.00 m | 50×3.0 | CL30,289*50 | 36pcs | |||

| 2.00 m | 50×3.0 | CL30,289*50 | 0pcs | |||||

| 1.70 m | 50×3.0 | CL30,289*50 | 18pcs | |||||

| Roof Components | roof conner 4 ways, use for roof beam truss | CS289×289 | 2pcs | |||||

| roof conner 5 ways, use for roof beam truss | CS289×289 | 2pcs | ||||||

| Connect plate with clamp | 4pcs | |||||||

| Single clamp | 36pcs | |||||||

| Double clamp | 16pcs | |||||||

| roof canopy material:pvc, Blue Colour or customized. | 507.06 | 1pcs | ||||||

packing weight: 4250kg

packing volume: 25cbm

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| 15.00 m Beam(front) | 4 sets | 3.00 m | 50×3.0 | CS389×389 | 20pcs | |||

| 2.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| 1.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| 24.00 m Beam(side) | 2 sets | 3.00 m | 50×3.0 | CS389×389 | 12pcs | |||

| 2.00 m | 50×3.0 | CS389×389 | 6pcs | |||||

| 1.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| 5.00 m Pillar | 8 sets | 3.00 m | 50×3.0 | CS389×389 | 8pcs | |||

| 2.00 m | 50×3.0 | CS389×389 | 8pcs | |||||

| 1.00 m | 50×3.0 | CS389×389 | 0pcs | |||||

| beam cube | Spigot cube 389x389 | 0pcs | ||||||

| Frame Tower | Spigot Sleeve Block S | 8pcs | ||||||

| Steel Base S | 8pcs | |||||||

| Top Section S | 8pcs | |||||||

| 1. Dragon stage brand, Load:1000kg, 2. Chain length:25m, 3. lifting speed:4m/min, 4. 380V-3phrase-50HZ 5. Double brake 6. G100 load chain, meeting 8:1/10:1 safety factor. 7. With 0.5M 4Pin-16A Europe plug 8. waterproof: IP54 | 8pcs | |||||||

| 1control 8pcs, with Handle case | 1pcs | |||||||

| Spigot Hinge Section,Height 1m | 8pcs | |||||||

| Fibre sling,BA04,2 tons 3m | 8pcs | |||||||

| Long outrigger | 32pcs | |||||||

| Item | Specification(squre truss) | Qty | ||||||

| length | main tube(mm) | size(mm) | ||||||

| Roof Pillar | 4 sets | 1.50 m | 50×3.0 | CS289×289 | 4pcs | |||

| 24.00 m Top Beam | 1 sets | 3.00 m | 50×3.0 | CS289×289 | 6pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 3pcs | |||||

| 1.00 m | 50×3.0 | CS289×289 | 0pcs | |||||

| 7.70 m Oblique Beam | 8 sets | 3.00 m | 50×3.0 | CS289×289 | 16pcs | |||

| 2.00 m | 50×3.0 | CS289×289 | 0pcs | |||||

| 1.70 m | 50×3.0 | CS289×289 | 8pcs | |||||

| 7.70 m Ladder truss | 18 sets | 3.00 m | 50×3.0 | CL30,289*50 | 36pcs | |||

| 2.00 m | 50×3.0 | CL30,289*50 | 0pcs | |||||

| 1.70 m | 50×3.0 | CL30,289*50 | 18pcs | |||||

| Roof Components | roof conner 4 ways, use for roof beam truss | CS289×289 | 2pcs | |||||

| roof conner 5 ways, use for roof beam truss | CS289×289 | 2pcs | ||||||

| Connect plate with clamp | 4pcs | |||||||

| Single clamp | 36pcs | |||||||

| Double clamp | 16pcs | |||||||

| roof canopy material:pvc, Blue Colour or customized. | 507.06 | 1pcs | ||||||

Best Practices for Proper Handling and Maintenance of Aluminum Trusses

Casting Brilliance: Mastering Lighting Truss Layout for Stunning Visuals

Behind the Scenes: Exploring Lighting Trusses and Studio Setup

How To Hang Lights On Truss - A Guide to Using Different Lighting Clamps

How to Prevent 200x200mm Aluminum Truss Deforming During the Welding

Understanding the Time-intensive Nature of Club Truss Production

FOSHAN DRAGON STAGE

No.7,Xiaxi Industrial Area,Heshun,Nanhai District,Foshan,528241,Guangdong,China.

+86 136 3132 8997